During the coronavirus pandemic, hundreds of millions of made-in-Vietnam surgical face masks have been exported abroad. This shows an upsurge in the operation and production capacity of the Vietnamese garment and textile sector. However, there are still many things to do to facilitate the sustainable export of surgical face masks.

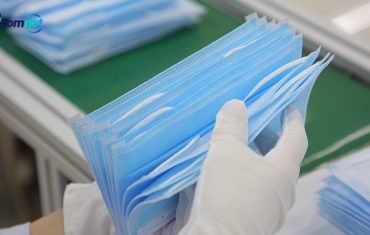

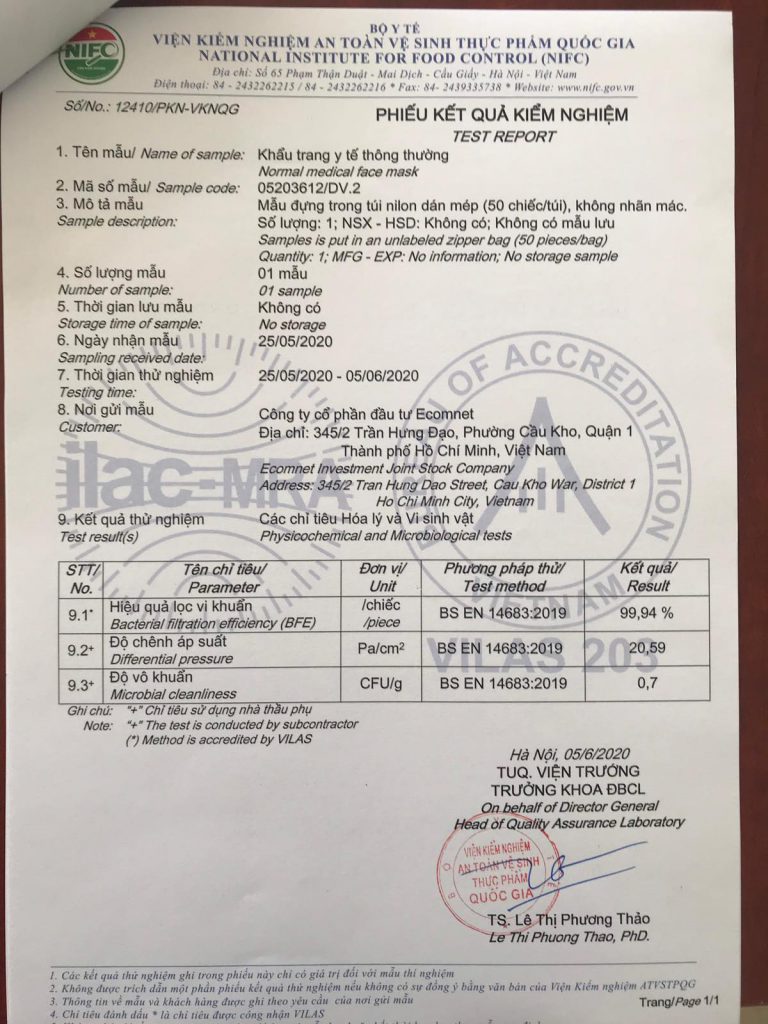

After recognizing the increasing demand for face masks amidst the epidemic outbreak, many companies found a way to transform the challenges into opportunities by switching to produce 3 ply surgical masks and 4 ply surgical masks.

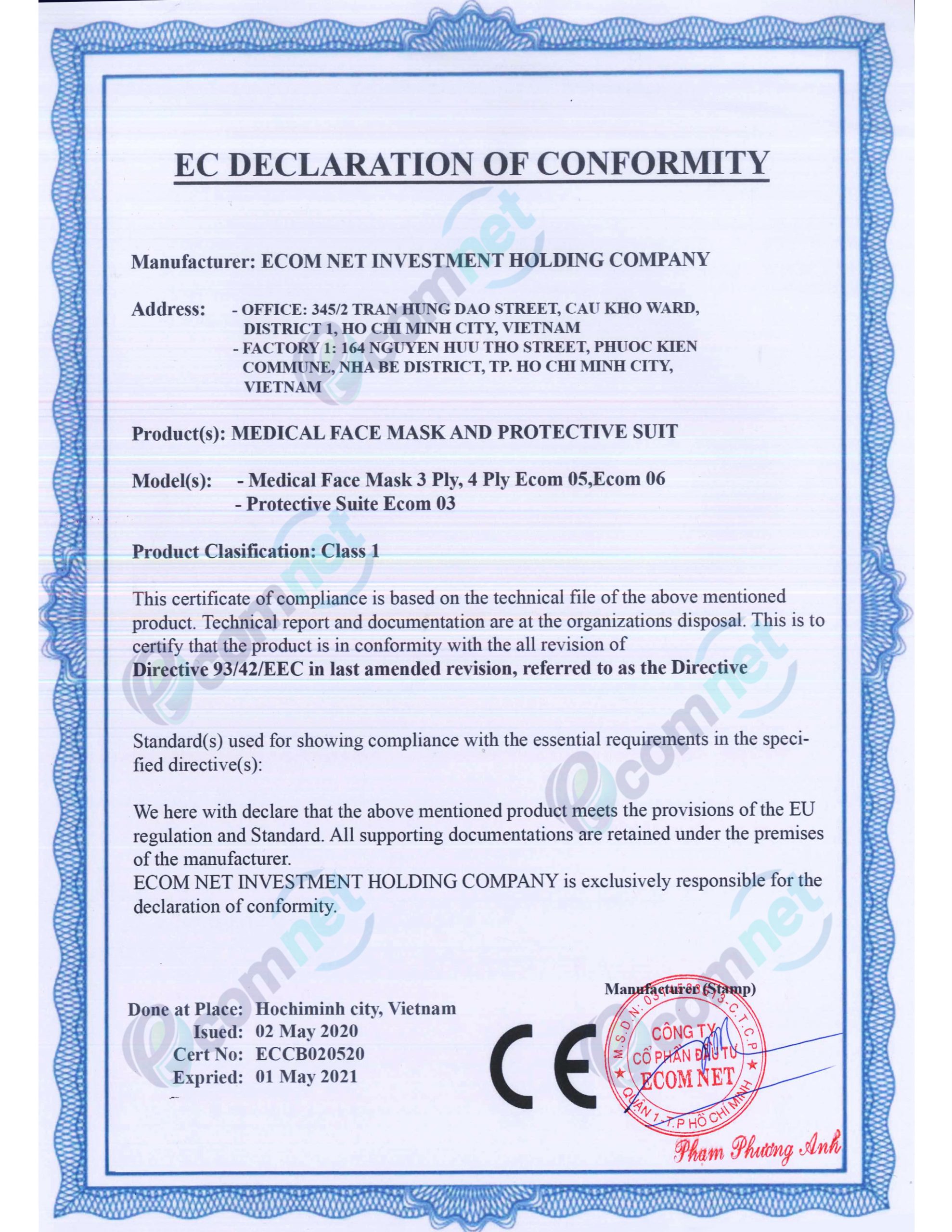

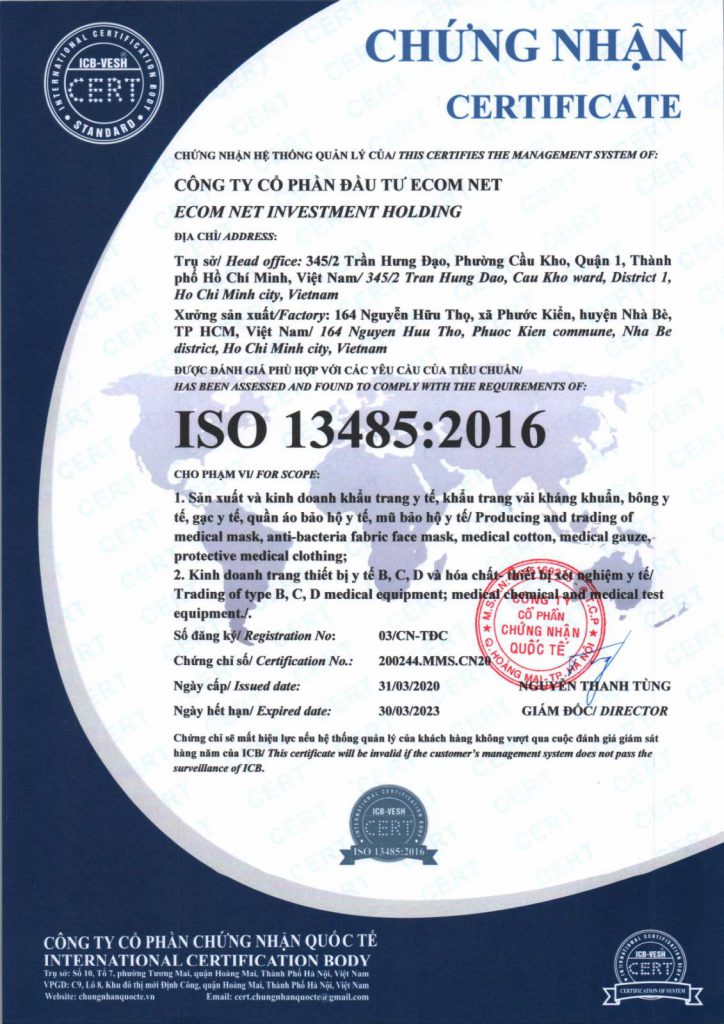

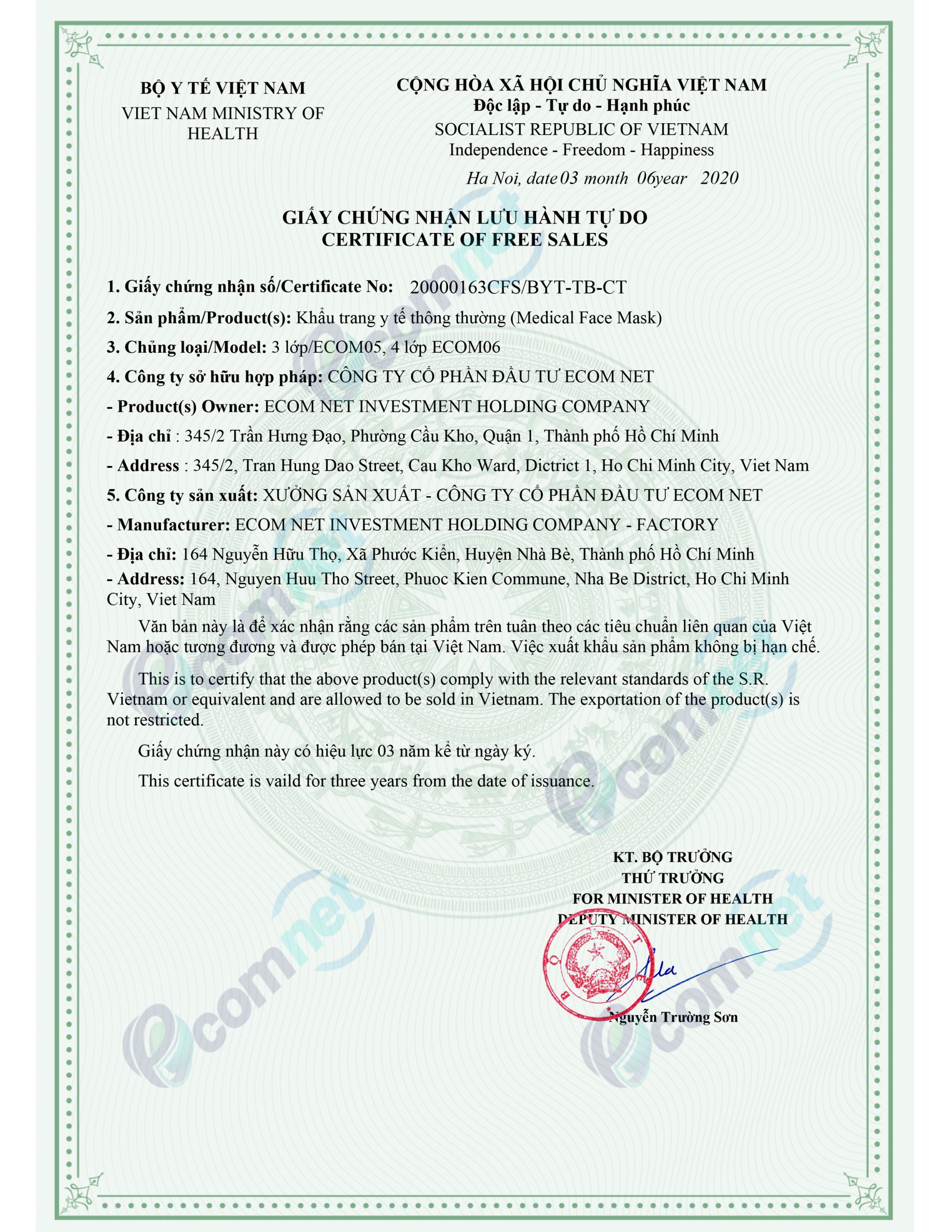

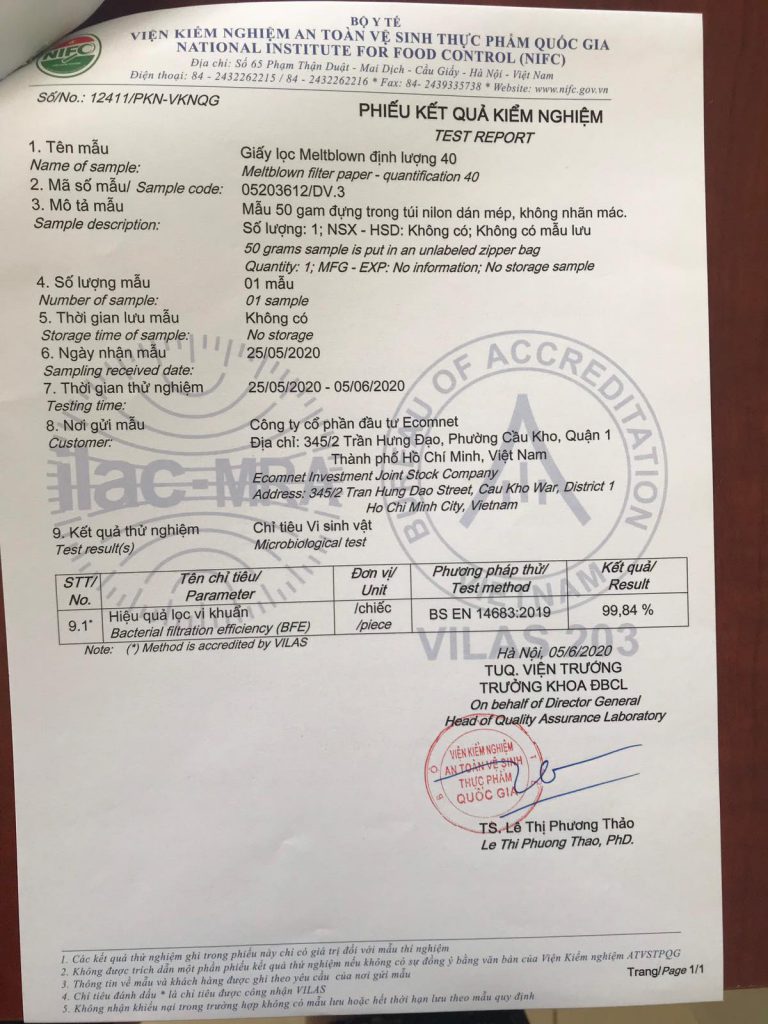

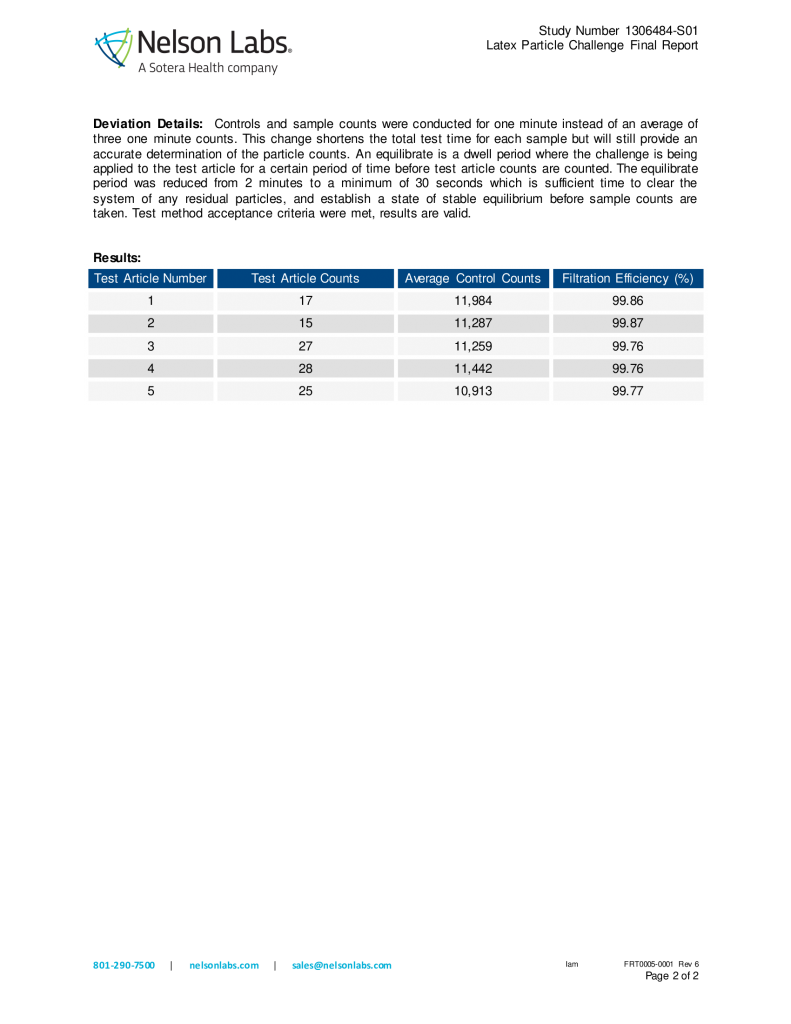

Face masks made by other Vietnamese garment and textile businesses have also achieved a strong position in export markets. As of April 19, Vietnam has exported over 415 million face masks. However, Vietnamese businesses have faced difficulties in meeting mask quality standards from importing countries. To export masks to the EU and the US, Vietnamese firms must obtain a CE marking and FDA certification. Therefore, they indicate that a product meets the appropriate safety and environmental protection standards. In a large demand for Vietnam surgical face masks, the EU and US may allow the import of these products without CE marking and FDA certification.

However, mask producers should well-prepare right from the start of the production process in order to raise their competitiveness. They also need to promote their exports 3 ply surgical masks and 4 ply surgical masks in the long term. Particularly focus on demanding markets like the US and EU. Vietnamese businesses will face competitiveness issues when other countries with success in developing their textile and garment sectors, including China and India.